30

2025

-

05

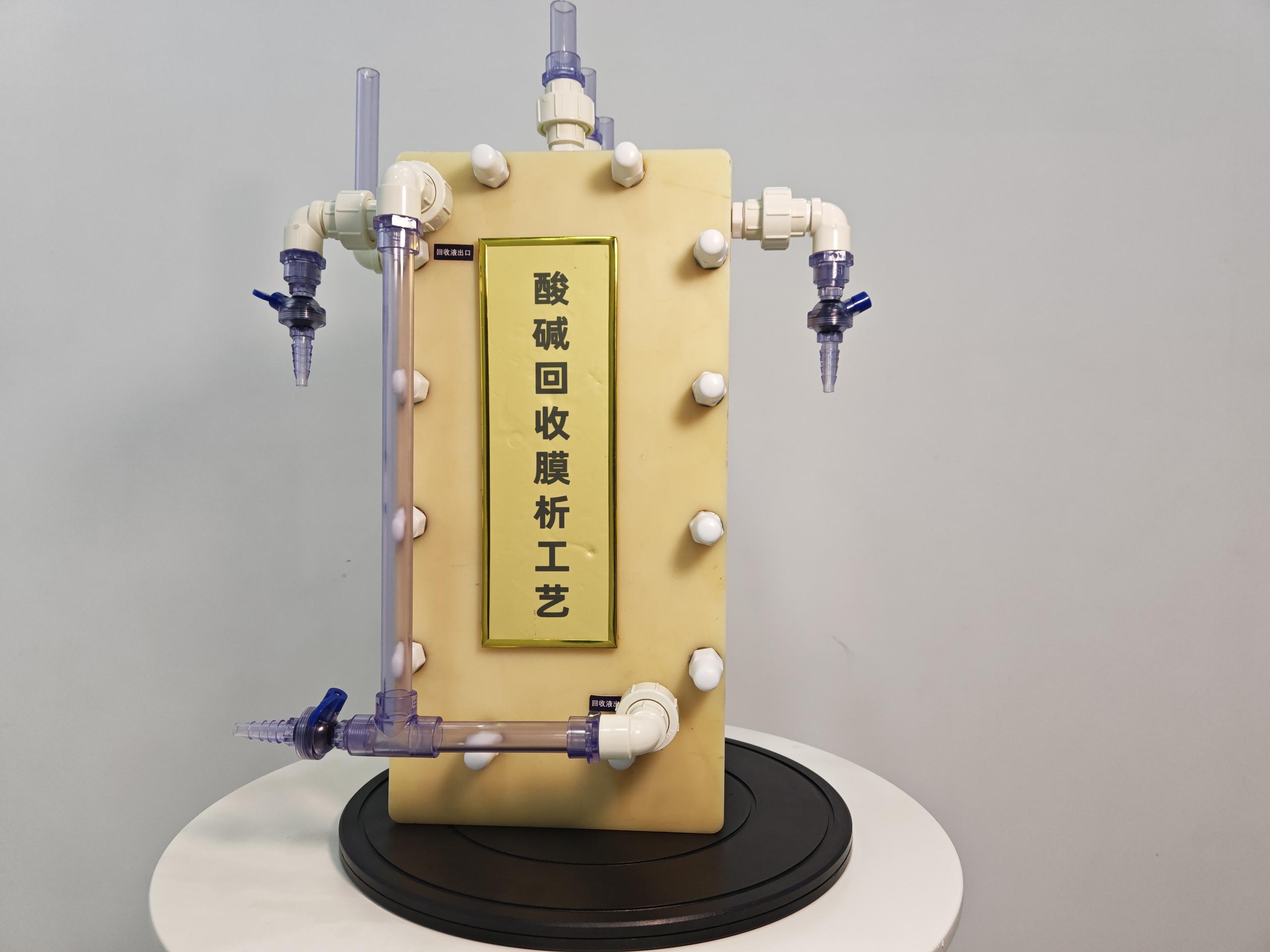

Application and Prospect of Membrane Separation Technology in Mixed Acid Recovery

Author:

With the rapid development of industry, mixed acids are increasingly used in industries such as chemical engineering, metallurgy, and electroplating. However, this also generates a large amount of mixed acid wastewater. If directly discharged, such wastewater not only causes resource waste but also severe environmental pollution. Therefore, developing efficient and environmentally friendly mixed acid recovery technologies is of great practical significance. As a new type of separation technology, membrane separation technology features low energy consumption, high separation efficiency, and no secondary pollution, showing broad application prospects in the field of mixed acid recovery.

I. Overview of Membrane Separation Technology

(1) Principles of Membrane Separation Technology

Membrane separation technology is a method that uses a special semi-permeable membrane to selectively separate, concentrate, or purify certain solutes or solvents (water) in a solution. During the membrane separation process, the semi-permeable membrane allows some substances to pass through while blocking others, achieving the separation of mixtures. According to different separation mechanisms, membrane separation technologies can be divided into electrodialysis, reverse osmosis, ultrafiltration, etc.

(2) Classification of Membrane Separation Technologies

- Electrodialysis: Under the action of a direct current electric field, anion and cation exchange membranes are used to selectively permeate anions and cations in the solution, separating solutes from water.

- Reverse Osmosis: Water molecules are driven to reverse osmose by applying pressure to concentrate solutions or wastewater. When the pressure applied to the solution side exceeds its osmotic pressure, water in the solution permeates through the semi-permeable membrane to the pure water side, while solutes are retained on the solution side.

- Ultrafiltration: After applying a certain pressure to the feed solution, macromolecules (molecular weight> 500), colloids, proteins, etc., are 截留 (截留) by the semi-permeable membrane, while solvents and low-molecular-weight substances (molecular weight < 500) pass through the membrane.

(3) Advantages of Membrane Separation Technology in Mixed Acid Recovery

- Efficient Separation: Membrane separation technology can achieve efficient separation based on differences in molecular size, charge properties, etc., of each component in the mixed acid, improving acid recovery rates.

- Energy Saving and Environmental Protection: Compared with traditional acid recovery methods, membrane separation technology does not require high temperature or pressure, has low energy consumption, and produces no secondary pollution.

- Simple Operation: The equipment has a simple structure, is easy to operate, and can be easily automated.

- Resource Recycling: Recovered acids can be reused in production, achieving resource recycling and reducing production costs.

II. Applications of Different Membrane Separation Methods in Mixed Acid Recovery

(1) Waste Acid Recovery by Dialysis Membrane Method

The dialysis membrane method is a membrane separation process driven by a concentration gradient, using anion exchange membranes (AEMs) to recover acids from salt solutions. During dialysis, the concentration of acid and its salts on the waste acid side is much higher than that on the water side. According to the principle of dialysis, due to the concentration gradient, the waste acid and its salts tend to diffuse into the diffusion chamber. However, the membrane is selectively permeable to anions, so anions on the waste acid side are attracted to pass through the membrane pores into the water side under the concentration gradient. Meanwhile, to maintain electroneutrality, cations are also 夹带 (entrained). Since H⁺ has a smaller hydrated radius and fewer charges, while metal salts have larger hydrated radii and more charges, H⁺ preferentially passes through the membrane, thus separating the acid from the waste liquid.

Example: Treating high-concentration sulfuric acid wastewater containing sodium sulfate by anion exchange membrane dialysis. Dynamic separation results show that the H₂SO₄ recovery rate reaches 83.4%, and the Na₂SO₄ content in the recovered acid decreases to 5.2 g/L. Acid wastewater from a textile factory contains approximately 10% Na₂SO₄, 7% H₂SO₄, and 1% COD by mass. Using the dialysis method, the recovery rate can reach 80%, the concentration ratio of recovered acid to waste acid is over 70%, and the salt rejection rate is 70%.

(2) Application of Reverse Osmosis in Mixed Acid Recovery

Reverse osmosis can concentrate mixed acid solutions to increase acid concentration. In some industrial processes, such as using nitric acid as a solvent in acrylic fiber production, the wastewater contains nitric acid. Electrodialysis (a form of reverse osmosis application) can concentrate 0.2% nitric acid to 10% for reuse in production.

Reverse osmosis has advantages such as high operating pressure, high separation efficiency, and high purity of recovered acid. Industrial devices include plate-and-frame, tubular, spiral-wound, and hollow-fiber types. According to chemical compositions, reverse osmosis membranes are classified into cellulose ester membranes and non-cellulose ester membranes.

(3) Application of Ultrafiltration in Mixed Acid Recovery

Ultrafiltration can 截留 (截留) macromolecules, colloids, etc., in mixed acids to achieve preliminary purification. During mixed acid recovery, ultrafiltration removes impurities such as proteins, starches, and bacteria, improving the quality of recovered acids.

The main separation mechanisms of ultrafiltration include pore size sieving on the membrane surface, hindrance due to membrane pore blockage, and primary adsorption of particles on the membrane surface and in pores. During ultrafiltration, due to the low diffusivity of macromolecules and high permeability of water, retained solutes accumulate on the membrane surface, causing a higher solute concentration on the membrane than in the bulk solution—a phenomenon called concentration polarization. Concentration polarization is reversible and can be mitigated by reducing the pressure difference across the ultrafiltration membrane or increasing the turbulent flow rate of the feed solution to lower solute concentration on the membrane surface, thereby restoring water flux and alleviating negative impacts on the ultrafiltration process.

III. Practical Application Cases of Membrane Separation Technology in Mixed Acid Recovery

(1) Treatment of Steel Pickling Waste Liquor

Pickling waste liquors in the steel industry include sulfuric acid, hydrochloric acid, and nitric acid/hydrofluoric acid solutions. Current membrane treatment technologies for steel pickling waste liquors use membrane ion selectivity to separate iron salts from acids, recovering both acid and iron salts. The process involves no phase change and offers high economic and environmental value. Specific membrane technologies for different purposes (acid recovery, concentration, wastewater discharge, etc.) include dialysis, nanofiltration, air-lift membrane reactors, membrane distillation, etc.

Example: A stainless steel plant uses spray roasting to regenerate mixed waste acid. The HF/HNO₃ waste acid containing metal salts is pumped to a waste acid storage tank, pressurized, sent to a Venturi pre-concentrator for heat exchange and pre-heating with roasting flue gas, filtered, and then sprayed into a spray roasting furnace via nozzles. The acid is atomized from the top of the furnace, where evaporation and thermal decomposition reactions occur, enabling effective waste acid recovery.

(2) Treatment of Acidic Wastewater from Textile Factories

Acidic wastewater from textile factories contains approximately 10% Na₂SO₄, 7% H₂SO₄, and 1% COD by mass. Traditional treatment involves alkali neutralization, imposing heavy economic burdens on enterprises. Using the dialysis method, the recovery rate reaches 80%, the concentration ratio of recovered acid to waste acid is over 70%, and the salt rejection rate is 70%. This not only reduces alkali consumption and production costs but also achieves resource recycling of waste acid.

IV. Development Prospects of Membrane Separation Technology in Mixed Acid Recovery

(1) Technological Innovation

With the continuous development of materials science and membrane technology, new membrane materials and modules are emerging. For example, membrane materials with higher selectivity, flux, and service life will be developed to further improve the efficiency and performance of membrane separation technology in mixed acid recovery.

(2) Application Expansion

Membrane separation technology has broad application prospects not only in traditional industries like chemical engineering and metallurgy but also in emerging fields such as new energy and environmental protection. For instance, it holds potential in recovering acidic wastewater from lithium battery production and acid recovery in wastewater treatment.

(3) Integration with Other Technologies

Membrane separation technology can be combined with other technologies such as evaporation, crystallization, and extraction to form more efficient and energy-saving mixed acid recovery processes. For example, integrating membrane separation with evaporation allows pre-concentration of mixed acids by membrane technology before evaporation and crystallization, further improving acid recovery rates and purity.

As an efficient membrane separation process, membrane separation technology has significant advantages and broad prospects in mixed acid recovery. Through different methods such as dialysis, reverse osmosis, and ultrafiltration, it can achieve efficient separation and recovery of various components in mixed acids. With continuous technological innovation and development, membrane separation technology will be widely applied in more fields, providing effective solutions for mixed acid recovery and resource recycling, and promoting sustainable industrial development.

Related Products

Flexible cabin: A green link connecting urban water conservation and ecological restoration

2025-11-14

Exploration of the Application of Membrane Chromatography Technology in the Recovery of Waste Alkali from Tungsten Metallurgy

2025-11-13

Membrane evolution technology: Green Innovation and Practical Breakthrough in Copper Smelting Processes

2025-11-12

From "Salt Disturbance" to "Salt Treasure" : Electrodialysis makes glycine production both environmentally friendly and cost-effective

2025-11-11

Huanke Environmental Protection Technology

HOTLINE:

Address:Optoelectronic Industry Accelerator in Weifang Hi-Tech Zone, Shandong Province, China

Contact:Zhang Gong

WhatsApp:+8619953608211

Email:eco.eqpt@gmail.com

Consult

TikTok

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd