22

2025

-

05

Exploration of Electrodialysis Applications in Circulating Water Treatment

Author:

1. Overview of Electrodialysis Technology

1.1 Basic Principles

Electrodialysis utilizes the selective permeability of semipermeable membranes to separate different solute particles (e.g., ions). Under an applied direct current (DC) electric field, charged solute particles (ions) in the solution migrate toward electrodes of opposite charge. The semipermeable membranes used in ED are ion exchange membranes, which can be classified into cation exchange membranes (cation membranes) and anion exchange membranes (anion membranes) based on ion charge properties. In electrolyte solutions, cation membranes allow cations to pass through while repelling anions, and anion membranes allow anions to pass through while repelling cations. Unlike ion exchange resins, ion exchange membranes in ED do not exchange ions with the solution but merely act as selective barriers for ions of different polarities.

1.2 Technical Classification

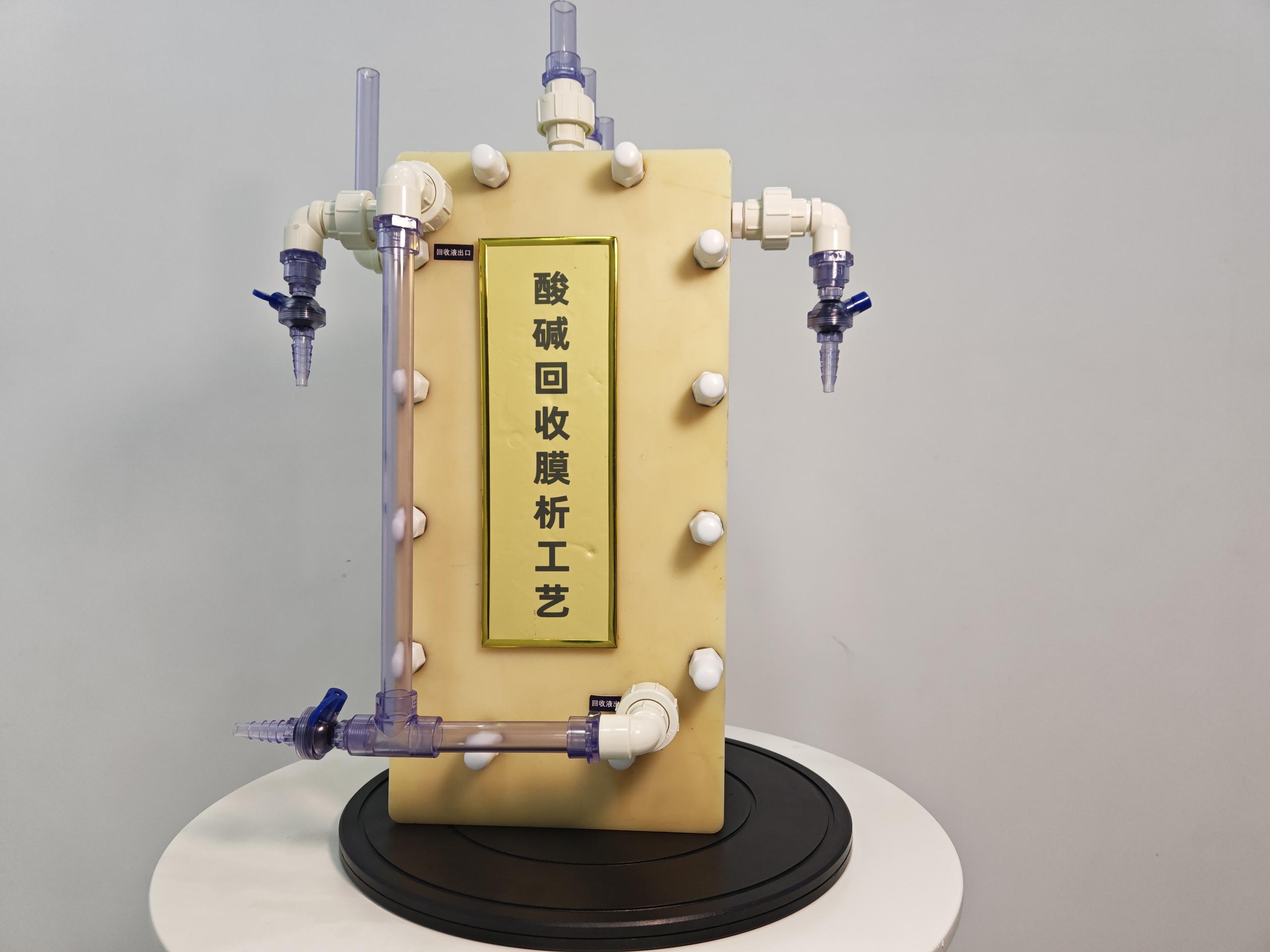

Depending on the types of ion-selective membranes and operational modes, electro-driven membrane separation processes can be divided into conventional electrodialysis, bipolar membrane electrodialysis, electrodialysis with electrolysis, selective electrodialysis, packed-bed electrodialysis, etc. Among them, conventional electrodialysis and bipolar membrane electrodialysis are two common membrane separation processes. Conventional electrodialysis achieves desalination and concentration of target solutions, while bipolar membrane electrodialysis uses bipolar membranes and conventional anion/cation exchange membranes to produce acids and alkalis from target solutions.

2. Roles of Electrodialysis in Circulating Water Treatment

2.1 Ion Removal

Circulating water contains various ions such as calcium ions (Ca²⁺), magnesium ions (Mg²⁺), and chloride ions (Cl⁻). The accumulation of these ions increases water hardness, forms scale, and reduces heat transfer efficiency and equipment performance. Electrodialysis technology uses the selective permeability of ion exchange membranes to separate ions from water, thereby reducing water hardness and minimizing scale formation.

2.2 Conductivity Reduction

Water conductivity is closely related to ion concentration: higher ion content leads to higher conductivity. By removing ions through electrodialysis, water conductivity can be effectively reduced, improving water purity and meeting the stringent water quality requirements of certain processes.

2.3 Concentration and Recovery

During circulating water treatment, electrodialysis can also concentrate and recover valuable substances from the water. For example, in some industrial processes, circulating water may contain valuable metal ions or chemical substances. ED technology can enrich these substances through concentration, enabling resource recycling and reducing production costs.

3. Practical Application Cases of Electrodialysis in Circulating Water Treatment

3.1 Circulating Water Treatment in a Power Plant

After long-term operation, the circulating water system of a power plant suffered from deteriorated water quality and excessive calcium and magnesium ion levels, leading to severe scaling in heat exchangers and reduced power generation efficiency. The plant adopted electrodialysis technology for water treatment. After operation, the calcium and magnesium ion concentrations in the circulating water significantly decreased, water hardness dropped, heat exchanger scaling was alleviated, and power generation efficiency improved. Additionally, ED concentrated and recovered partial valuable water resources, reducing freshwater consumption.

3.2 Circulating Water Treatment in a Chemical Enterprise

The circulating water system of a chemical enterprise contained high levels of chloride and sulfate ions, which caused strong corrosion to equipment and shortened its service life. The enterprise introduced electrodialysis technology, which effectively removed chloride and sulfate ions from the water, reducing corrosivity and extending equipment life. Furthermore, the recovered concentrated solution could be further treated and reused, achieving resource recycling.

4. Challenges Facing Electrodialysis in Circulating Water Treatment

4.1 Cost Issues

Electrodialysis involves high investment costs, including expenses for membrane materials, electrode materials, and equipment manufacturing. Additionally, the process consumes electrical energy, resulting in relatively high operational costs. These factors limit the large-scale application of ED in circulating water treatment.

4.2 Membrane Fouling

During circulating water treatment, impurities and microorganisms in the water may deposit on the membrane surface, causing membrane fouling. Fouling reduces membrane flux and separation efficiency, increases membrane cleaning and replacement frequency, and raises operational and maintenance costs.

4.3 Technical Integration Issues

Circulating water treatment systems are typically complex engineering systems requiring integration with other processes (e.g., pretreatment, post-treatment). Currently, the integration of electrodialysis with other processes is insufficient, necessitating further research and development to optimize the entire treatment system and achieve automated control.

5. Future Development Directions

5.1 Development of New Membrane Materials

Increasing R&D efforts to develop new membrane materials with high selective permeability, fouling resistance, long lifespan, and low cost will reduce ED technology costs and enhance its market competitiveness.

5.2 Process Flow Optimization

Further optimizing electrodialysis processes to improve separation efficiency, recovery rates, and energy efficiency is essential. Integrating ED with other treatment processes will promote efficient and stable operation of circulating water treatment systems.

5.3 Expansion of Application Fields

Beyond traditional industries like power and chemicals, expanding electrodialysis applications to sectors such as construction, agricultural irrigation, and domestic water will contribute more to water resource conservation and recycling.

Electrodialysis technology plays significant roles in circulating water treatment, including ion removal, conductivity reduction, and resource concentration/recovery, with proven effectiveness in practical applications. However, challenges such as high costs, membrane fouling, and integration issues remain. In the future, enhancing R&D of new membrane materials, optimizing processes, and expanding application fields will drive the further development of electrodialysis in circulating water treatment, providing technical support for sustainable water resource utilization.

Related Products

Application of Membrane Separation Technology in the Recovery of HCl and H₂SO₄ in Pharmaceutical Engineering

2025-06-04

Application and Prospect of Membrane Separation Technology in Mixed Acid Recovery

2025-05-30

Exploration on the Application of Membrane Separation Technology in Alkali Recovery of Aluminum Alloy Profile Processing

2025-05-30

Sodium Hydroxide Recovery Technology in Tungsten Metallurgy Industry

2025-05-27

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd