28

2025

-

06

The Application of Membrane Separation Technology in the Recycling and Resource-saving Circular Utilization of 15% Waste Hydrochloric Acid in Electroplating Plants

Author:

As an important part of the manufacturing industry, the electroplating industry generates a large amount of waste hydrochloric acid containing heavy metal ions (such as iron, copper, nickel) and unreacted acid during production. If directly discharged without effective treatment, this waste hydrochloric acid not only causes serious environmental pollution but also leads to the waste of valuable hydrochloric acid resources. With the improvement of environmental awareness and the demand for resource circular utilization, electroplating plants have put forward higher requirements for the recycling of waste hydrochloric acid and resource-saving circular utilization. As an efficient separation and purification method, membrane separation technology has shown great application potential in the recycling of 15% waste hydrochloric acid in electroplating plants.

1. Characteristics and Treatment Status of 15% Waste Hydrochloric Acid in Electroplating Plants

1. Characteristics and Treatment Status of 15% Waste Hydrochloric Acid in Electroplating Plants

(1) Characteristics of Waste Hydrochloric Acid

The waste hydrochloric acid produced by electroplating plants usually contains a certain concentration of free acid (about 15%), heavy metal ions (such as iron, copper, nickel), and other impurities such as organic pollutants. This complex composition makes the waste hydrochloric acid difficult to treat.

(2) Current Treatment Status

At present, for treating waste hydrochloric acid, traditional methods such as neutralization precipitation are simple to operate but generate a large amount of hard-to-treat sludge and cannot effectively recover hydrochloric acid, leading to resource waste. Advanced treatment methods such as spray roasting can realize the regeneration and recovery of hydrochloric acid, but their high equipment investment and treatment costs limit their promotion in small and medium-sized electroplating plants. Therefore, developing an efficient and economical waste hydrochloric acid recycling technology has become an urgent problem to be solved in the electroplating industry.

2. Principles and Advantages of Membrane Separation Technology in Waste Hydrochloric Acid Recycling

(1) Principles of Membrane Separation Technology

Membrane separation technology uses the selective permeability of semi-permeable membranes to separate useful components (such as hydrochloric acid) from impurities (such as heavy metal ions and organic pollutants) in waste hydrochloric acid. Commonly used membrane separation technologies include:

- Membrane dialysis method: Utilizes the selective permeation of anion exchange membranes to allow hydrochloric acid to pass through the membrane while retaining heavy metal ions.

- Electrodialysis method: Under the action of an electric field, through the selective permeation of ion exchange membranes, metal ions and acid are separated.

- Reverse osmosis method: Uses the selective permeation of reverse osmosis membranes to separate hydrochloric acid from waste hydrochloric acid.

(2) Advantages of Membrane Separation Technology

- Efficient separation: It can achieve high-efficiency separation of hydrochloric acid and impurities in waste hydrochloric acid. The recovered hydrochloric acid has high purity and can be directly reused in electroplating processes, improving resource utilization.

- Environmental protection and energy saving: Compared with traditional waste hydrochloric acid treatment methods, it does not require adding a large number of chemical reagents, reducing the generation of secondary pollution. Meanwhile, it has low energy consumption, meeting the requirements of energy conservation and emission reduction.

- Simple operation: The equipment has a high degree of automation, simple operation, and low maintenance costs, enabling continuous and stable operation and improving production efficiency.

3. Specific Applications of Membrane Separation Technology in Recycling 15% Waste Hydrochloric Acid in Electroplating Plants

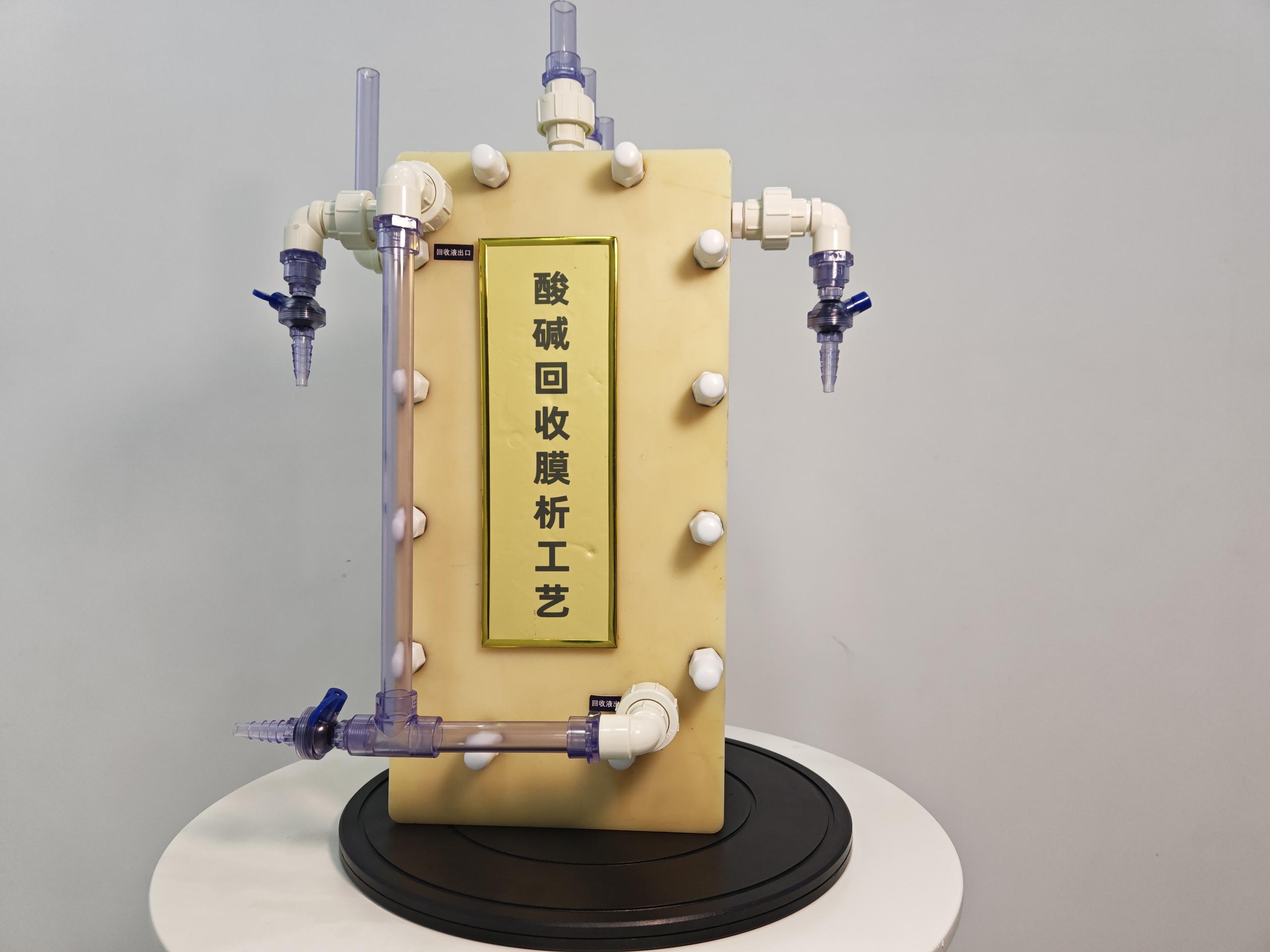

(1) Application of Membrane Dialysis Method

The membrane dialysis method is a commonly used membrane separation technology for waste hydrochloric acid recycling in electroplating plants. Through the selective permeation of anion exchange membranes, hydrochloric acid molecules in waste hydrochloric acid can pass through the membrane into the recovery solution, while heavy metal ions and other impurities are retained in the original solution. This method has high treatment efficiency, low energy consumption, and relatively low operation costs. For example, an electroplating plant adopted the membrane dialysis method to treat 15% waste hydrochloric acid, successfully increasing the hydrochloric acid recovery rate to over 90%, and the concentration of the recovered hydrochloric acid can reach about 80% of the original waste hydrochloric acid concentration, realizing effective recycling of hydrochloric acid.

(2) Application of Electrodialysis Method

Electrodialysis is also an important technology for waste hydrochloric acid recycling in electroplating plants. Under the electric field, the anion and cation exchange membranes in the electrodialyzer have selective permeability to anions and cations in the solution, causing hydrochloric acid molecules to move toward the cathode and pass through the anion membrane into the recovery chamber, while heavy metal ions move toward the anode and are retained in the original solution chamber by the cation membrane. This method can effectively separate hydrochloric acid and heavy metal ions, and the recovered hydrochloric acid has high purity. For instance, an electroplating plant used the electrodialysis method to treat 15% waste hydrochloric acid. By optimizing operation parameters, the hydrochloric acid recovery rate was increased to over 95%, and the quality of the recovered hydrochloric acid was stable, which could be directly reused in the electroplating process.

(3) Coupling Application of Membrane Separation Technology with Other Technologies

To improve the efficiency and quality of waste hydrochloric acid recycling, membrane separation technology is often coupled with other technologies. For example, combining membrane separation technology with ion exchange resin method, most heavy metal ions in waste hydrochloric acid can be removed by membrane separation first, and then residual metal ions can be further removed by ion exchange resin to improve the purity of recovered hydrochloric acid. In addition, membrane separation technology can also be combined with evaporation crystallization technology, extraction technology, etc., to achieve comprehensive recovery and utilization of multiple components in waste hydrochloric acid.

4. Challenges and Solutions in the Application of Membrane Separation Technology

(1) Membrane Fouling Problem

Membrane fouling is a common problem in the application of membrane separation technology. It will lead to a decrease in membrane flux and separation efficiency, increase the frequency of membrane cleaning and replacement, and raise operation costs and maintenance difficulties. Solutions include:

- Optimize the pretreatment process: Pretreat waste hydrochloric acid before membrane separation to remove impurities such as suspended solids, colloids, and macromolecular organic matter, reducing the pollution load on membrane modules. For example, filtering and sedimentation can effectively reduce the occurrence of membrane fouling.

- Develop new anti-fouling membrane materials: Increase R&D efforts on new membrane materials with high anti-fouling performance and long service life to improve membrane stability and service life. For instance, developing membrane materials with special surface properties can reduce the adsorption and deposition of impurities on the membrane surface, lowering the risk of membrane fouling.

- Optimize the membrane cleaning process: Select appropriate cleaning agents and methods according to the type and degree of membrane fouling, and regularly clean membrane modules to restore membrane flux and separation performance. For example, combining chemical cleaning with physical cleaning can effectively remove pollutants on the membrane surface and extend membrane life.

(2) Technical Cost Problem

The equipment investment and operation costs of membrane separation technology are relatively high, limiting its promotion in some small and medium-sized electroplating plants. Solutions include:

- Optimize process design: Reduce equipment investment and operation costs by optimizing process flows and equipment selection. For example, reasonably select the type and specification of membrane modules to improve membrane utilization and treatment efficiency; optimize the operation parameters of electrodialysis technology to reduce energy consumption.

- Strengthen localization of equipment: Increase R&D efforts on domestic key equipment and technologies to reduce equipment procurement costs. Meanwhile, improve equipment reliability and stability to reduce maintenance and replacement costs.

- Policy support and subsidies: Governments can introduce relevant policies to provide financial support and tax incentives to electroplating plants that adopt membrane separation technology for waste hydrochloric acid recycling, encouraging enterprises to use advanced waste liquid treatment technologies.

5. Conclusions and Prospects

Membrane separation technology has important application value in the recycling of 15% waste hydrochloric acid and resource-saving circular utilization in electroplating plants. Through the application of membrane separation methods (such as membrane dialysis and electrodialysis), efficient separation and purification of hydrochloric acid and impurities in waste hydrochloric acid can be achieved, improving resource utilization and reducing environmental pollution risks. Although challenges such as membrane fouling and technical costs exist in the application process, these problems can be effectively solved by optimizing the pretreatment process, developing new anti-fouling membrane materials, and optimizing process design.

In the future, with the continuous development and innovation of membrane separation technology, its application prospects in waste hydrochloric acid recycling in electroplating plants will be broader, expected to provide strong support for the sustainable development of the electroplating industry. Meanwhile, governments, enterprises, and all sectors of society should work together to increase R&D and promotion efforts for membrane separation technology, promoting the electroplating industry to achieve green, circular, and sustainable development.

Related Products

The Renewable Fiber Filter: An Innovative Force in Oil Removal

2025-06-28

The Application of Membrane Separation Technology in the Recycling and Resource-saving Circular Utilization of 15% Waste Hydrochloric Acid in Electroplating Plants

2025-06-28

Fully Renewable Fiber Filters: A Water Treatment Revolution Beyond Quartz Sand Filters

2025-06-24

Exploration on the Application of Electrodialysis Technology in Desalination of Soy Peptone

2025-06-24

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd