07

2025

-

07

Application of Membrane Dialysis in Waste Acid Recovery of Iron and Steel Industry

Author:

一、Principle of Membrane Dialysis Technology

Membrane dialysis is a membrane separation technology that achieves substance separation based on the selective permeability of ion-exchange membranes. In the field of waste acid recovery in the iron and steel industry, anion exchange membranes (anion membranes) are mostly used. Anion membranes carry positive charges due to the presence of fixed positive charge groups inside, which can attract anions in the solution while repelling cations.

Membrane dialysis is a membrane separation technology that achieves substance separation based on the selective permeability of ion-exchange membranes. In the field of waste acid recovery in the iron and steel industry, anion exchange membranes (anion membranes) are mostly used. Anion membranes carry positive charges due to the presence of fixed positive charge groups inside, which can attract anions in the solution while repelling cations.

During membrane dialysis, the concentration difference serves as the driving force. The waste acid solution, as the feed liquid, contains high concentrations of anions such as sulfate ions (SO₄²⁻), while the receiving liquid typically uses tap water with a relatively low anion concentration. According to the principle of concentration gradient, anions in the waste acid solution spontaneously diffuse to the receiving liquid side. Meanwhile, the hydroxide ions (OH⁻) with higher concentration in the receiving liquid pass through the anion membrane into the waste acid solution side. In the waste acid solution, OH⁻ combines with hydrogen ions (H⁺) to form water, gradually reducing the H⁺ concentration and thus decreasing the overall acid concentration of the waste acid solution.

After a period of membrane dialysis, recovered acid can be obtained from the receiving liquid side. Impurities and metal ions in the waste acid solution, due to their large ionic radius, are difficult to pass through the anion membrane and are retained in the original solution chamber, forming residue liquid containing impurities. In this way, effective separation of acid from impurities and metal ions is achieved.

二、Practical Application Cases

(一) Case Background

A hardware factory mainly produces various hardware products. In the steel pickling process, sulfuric acid is used to remove the oxide layer and impurities on the steel surface to ensure the quality and performance of the steel. However, this process generates a large amount of waste liquid containing sulfuric acid. Tests show that the original waste acid solution has a sulfuric acid content of 60-80 g/L and ferrous sulfate content of 150-200 g/L. If these waste liquids are directly discharged, they will not only cause serious pollution to the surrounding environment but also lead to the waste of sulfuric acid resources and increase the production cost of the enterprise.

(二) Treatment Process

After in-depth market research and technical evaluation, the factory decided to introduce membrane dialysis equipment for waste acid recovery. After the equipment was installed and debugged, the original waste acid solution was used as the feed liquid, and tap water was used as the receiving liquid, which were respectively introduced into the corresponding compartments of the membrane dialysis equipment. Driven by the concentration difference, sulfate ions in the waste acid solution began to diffuse to the receiving liquid side, while OH⁻ in the receiving liquid entered the waste acid solution side and combined with H⁺ to form water. The equipment ran continuously for a period until the waste acid recovery was completed.

(三) Treatment Effect

After treatment by the membrane dialysis equipment, the acid recovery rate reached 70%. The recovered acid solution had a sulfuric acid content of 42-56 g/L and ferrous sulfate content below 15 g/L. The recovered sulfuric acid could be reused in the pickling process, reducing the enterprise's demand for fresh sulfuric acid; substances such as ferrous sulfate in the residue liquid could be further processed for recycling or safe disposal. By recovering sulfuric acid and ferrous sulfate, the entire equipment investment was repaid through sales revenue within two years. This not only reduced the production cost of the enterprise but also reduced environmental pollution, achieving a win-win situation of economic and environmental benefits.

三、Advantage Analysis

(一) Energy Conservation and Environmental Protection

The membrane dialysis process relies solely on the concentration difference as the driving force without consuming additional energy such as heating or pressurization. Compared with other treatment methods such as evaporation concentration and ion exchange, its energy consumption is extremely low. Evaporation concentration requires a large amount of thermal energy to evaporate the water in the waste acid solution, while ion exchange requires the use of chemical reagents for regeneration, both of which consume a lot of energy and resources. Membrane dialysis technology avoids these additional energy consumptions, greatly reducing the enterprise's energy consumption and production costs.

At the same time, the membrane dialysis process does not produce secondary pollution. As a physical separation process, it involves no chemical reactions and introduces no new pollutants. The traditional lime neutralization method generates a large amount of waste residue containing heavy metal ions and harmful substances, which will cause secondary pollution to soil and water sources if not properly treated. Membrane dialysis technology avoids this problem and is environmentally friendly.

(二) Efficient Recovery

Membrane dialysis technology can efficiently separate acid from impurities and heavy metal ions in waste acid. Under appropriate operating conditions, the acid recovery rate can reach 70%-90%. By recovering acid, the reuse of acid resources is realized, reducing the enterprise's demand for fresh acid and the procurement cost of raw materials. For iron and steel enterprises, acid raw materials such as sulfuric acid are important production costs, and the recycling of waste acid can significantly reduce production costs and improve the economic benefits of enterprises.

In addition, membrane dialysis technology has a high interception rate for impurities and metal ions, which can effectively remove harmful substances in the waste acid solution and improve the quality of the recovered acid. The recovered acid can be directly used in the production process without complicated purification treatment, further reducing production costs.

(三) Simple Operation

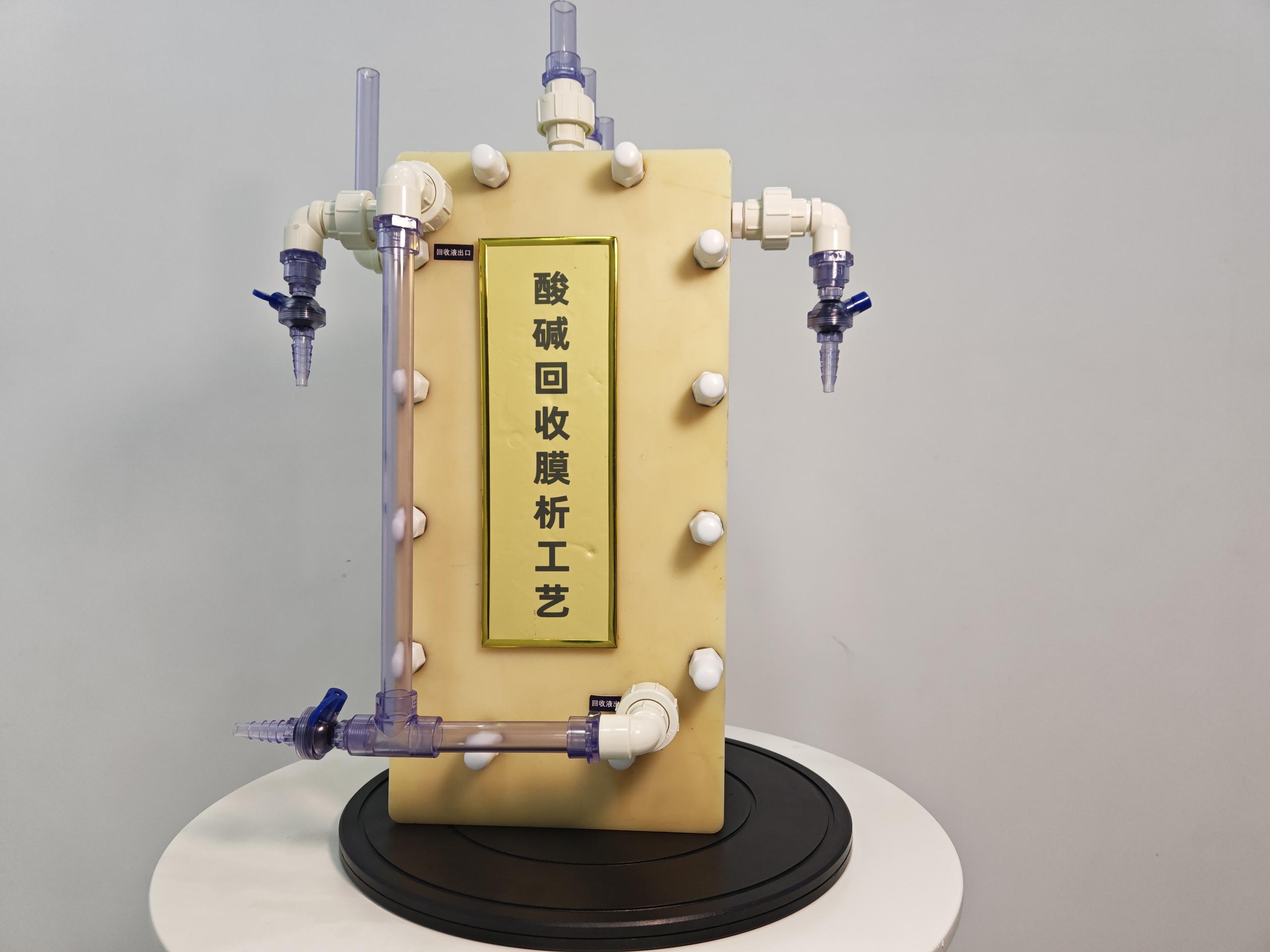

Membrane dialysis equipment has a simple structure, mainly composed of membrane modules, compartments, pipelines, etc. It is convenient to operate with low operation and maintenance costs. During the operation of the equipment, only regular inspection of membrane performance and equipment operation status, as well as simple cleaning and maintenance, are required. It does not require complex operation processes or professional technicians, and ordinary workers can get started after simple training. This makes the technology suitable for large-scale promotion and application in industrial production, especially for small and medium-sized enterprises.

四、Conclusion

Membrane dialysis technology has significant advantages in waste acid recovery of the iron and steel industry. It can not only efficiently recover acid resources from waste acid, reduce the production cost of enterprises, but also reduce environmental pollution and achieve the goal of energy conservation and environmental protection. With the continuous improvement of environmental protection requirements and the increasing importance of resource recycling, iron and steel enterprises are facing growing environmental pressure and resource constraints. As an advanced waste acid recovery technology, membrane dialysis technology conforms to the concept of sustainable development and will be more widely applied and developed in the iron and steel industry.

In the future, with the continuous progress of membrane material science and membrane separation technology, the performance of membrane dialysis technology will continue to improve, and the recovery rate and separation effect will be further optimized. At the same time, the degree of automation of the equipment will also continue to increase, and the operation will be more convenient. Iron and steel enterprises should actively promote and apply membrane dialysis technology, strengthen technological innovation and management innovation, improve the level of waste acid recycling, and achieve the coordinated development of economic, social and environmental benefits.

Related Products

Application of Membrane Dialysis in Waste Acid Recovery of Iron and Steel Industry

2025-07-07

Flexible Tank Reclaimed Water: A Technological Tool to Crack the Water Shortage Crisis

2025-07-07

Application of Membrane Dialysis in Acid Recovery of Aluminum Processing Industry

2025-07-04

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

WhatsApp:+8619953608211

Email:eco.eqpt@gmail.com

Consult

TikTok

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd