23

2025

-

09

Electrodialysis is used for the concentration and evaporation reduction strategies of salts such as sodium nitrate

Author:

In industries such as chemical engineering, rare earth catalysts, and oil refining catalysts, the treatment of wastewater with salts like sodium nitrate has always been a difficult problem. Although the traditional evaporation concentration method is effective, it has high energy consumption, large equipment investment, and is prone to problems such as scaling. Electrodialysis technology, as an efficient membrane separation technique, has demonstrated great application potential in the concentration of salts such as sodium nitrate in recent years. It can effectively reduce the volume of evaporation and lower treatment costs.

I. Principles and Advantages of Electrodialysis Technology

(1) Principle of Electrodialysis Technology

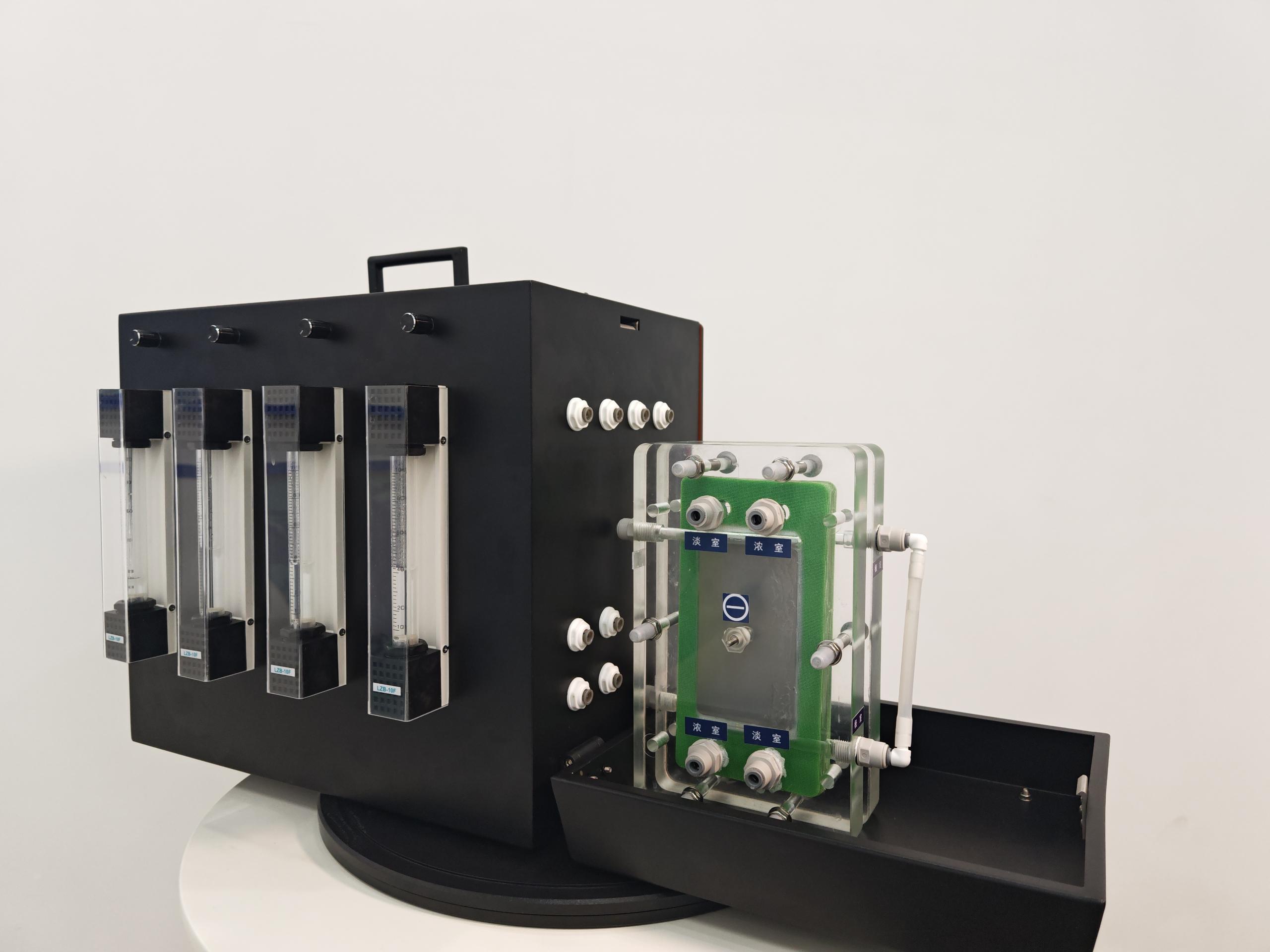

Electrodialysis technology takes advantage of the selective permeability of ion-exchange membranes. Under the action of an external direct current electric field, cations and anions in the solution are directed to migrate and selectively pass through the membrane. Inside the electrodialyzer, multiple sets of alternately arranged anion and cation exchange membranes separate the solution into concentrated water chambers and fresh water chambers. Cations pass through the cation membrane and move towards the negative electrode, while anions pass through the anion membrane and move towards the positive electrode. Thus, a high-concentration salt solution is formed in the concentrated water chamber, and low-salinity fresh water is obtained in the fresh water chamber.

(2) Advantages of electrodialysis technology

High-efficiency concentration: Electrodialysis technology can efficiently concentrate salts such as sodium nitrate from low-concentration solutions to higher concentrations, reducing the volume of subsequent evaporation treatment.

Energy conservation and environmental protection: Compared with traditional evaporation concentration methods, electrodialysis technology has lower energy consumption and does not generate a large amount of secondary pollutants.

Easy operation: The structure of the electrodialysis device is relatively simple, easy to operate, and convenient for maintenance and upkeep.

Strong adaptability: Electrodialysis technology has relatively low requirements for the pretreatment of raw water and can adapt to the treatment of sodium nitrate wastewater of different concentrations and compositions.

Ii. Application Cases of Electrodialysis Technology in the Concentration of Salts such as Sodium Nitrate

(1) Treatment of sodium nitrate wastewater in the rare earth catalyst industry

During the production process of rare earth oxide catalysts, a large amount of 3% to 5% sodium nitrate wastewater is generated. The homogeneous membrane electrodialysis device can be used to concentrate sodium nitrate to over 20%, which then enters the evaporation system for further processing. This process has addressed the issues of low concentration ratios and poor resistance to metal ion contamination of heterogeneous membranes and some imported homogeneous membranes. At the same time, it has achieved zero discharge and resource utilization of wastewater containing sodium nitrate.

(2) Ammonium nitrate wastewater treatment in the oil refining catalyst industry

About 3% of ammonium nitrate wastewater is generated during the production process of oil refining catalysts. The homogeneous membrane electrodialysis device was adopted for concentration and desalination. After the concentration of ammonium nitrate in the concentrated water reached 20%, it entered the evaporation system. The fresh water from electrodialysis was treated by reverse osmosis and reused, achieving the resource utilization and zero discharge of wastewater containing ammonium nitrate.

(3) Other applications for salt concentration

In addition to sodium nitrate and ammonium nitrate, electrodialysis technology can also be used for the concentration of other salts such as ammonium chloride and sodium bromide. For instance, in the nano-zirconium industry, homogeneous membrane electrodialysis devices are used to treat ammonium chloride wastewater. The concentrated water from electrodialysis, containing 17% ammonium chloride, enters the MVR evaporation system to produce solid ammonium chloride for sale. The fresh water from electrodialysis, after further treatment, is returned to the workshop for reuse.

Iii. Strategies for Reducing Evaporation Volume

(1) Optimize the process parameters of electrodialysis

By optimizing the process parameters such as operating current, voltage and flow rate of electrodialysis, the concentration efficiency of electrodialysis can be enhanced and the volume of wastewater entering the evaporation system can be reduced. For instance, appropriately increasing the operating current and voltage can accelerate the migration rate of ions and enhance the concentration ratio.

(2) Adopt multi-stage electrodialysis in series

By adopting a multi-stage electrodialysis series connection method, the concentration of salts such as sodium nitrate can be gradually increased, and the volume of wastewater eventually entering the evaporation system can be reduced. Each stage of the electrodialyzer further concentrates the salt in the wastewater, reducing the burden of subsequent evaporation treatment.

(3) Combine with other separation technologies

Combining electrodialysis technology with other separation techniques such as diffusion dialysis and reverse osmosis can achieve more efficient salt concentration and wastewater reuse. For instance, diffusion dialysis technology is first adopted to remove most of the free acids in the wastewater. Then, electrodialysis technology is used to further concentrate the residual liquid from dialysis. Finally, the concentrated water is sent to the evaporation system for treatment.

(4) Enhance the efficiency of the evaporation system

Although electrodialysis technology can reduce the volume of evaporation, the evaporation system remains a key link in handling high-concentration salt solutions. By adopting advanced evaporation technologies such as MVR evaporation and multi-effect evaporation, the efficiency of the evaporation system can be enhanced, and energy consumption and operating costs can be reduced.

Iv. Conclusions and Prospects

Electrodialysis technology has significant application value in the concentration of salts such as sodium nitrate, which can effectively reduce the volume of evaporation and lower treatment costs. By optimizing the process parameters of electrodialysis, adopting multi-stage electrodialysis series connection, integrating other separation technologies, and enhancing the efficiency of the evaporation system, the treatment effect and economy of electrodialysis technology can be further improved. In the future, with the continuous optimization of membrane materials and the continuous development of electrodialysis technology, its application prospects in the concentration of salts such as sodium nitrate will be even broader, and it is expected to provide more efficient and environmentally friendly solutions for wastewater treatment in industries such as chemical engineering, rare earth catalysts, and oil refining catalysts.

Related Products

Electrodialysis is used for the concentration and evaporation reduction strategies of salts such as sodium nitrate

2025-09-23

Electrodialysis Empowering Methionine Production: Application Paths and Practical Exploration

2025-09-22

Cysteine separation and purification: Application and Progress of Electrodialysis

2025-09-22

Electrodialysis Empowering Lysine Separation and Purification: Current Application Status and Cutting-edge Progress of the technology

2025-09-18

Huanke Environmental Protection Technology

HOTLINE:

Address:Optoelectronic Industry Accelerator in Weifang Hi-Tech Zone, Shandong Province, China

Contact:Zhang Gong

WhatsApp:+8619953608211

Email:eco.eqpt@gmail.com

Consult

TikTok

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd