13

2025

-

08

Membrane separation: Green and efficient acid recovery for rare earth metallurgical leachate

Author:

In the leaching process of the rare earth and metallurgical industries, waste liquid containing high concentrations of free acids (such as phosphoric acid and oxalic acid) and metal ions (such as rare earth ions and iron ions) is produced. Although traditional neutralization treatment can reduce acid, it causes waste of acid resources and secondary pollution of metal salts, becoming a bottleneck for the green development of the industry. Membrane chromatography technology, with its low energy consumption and high selectivity, is becoming the key to solving this problem and providing a brand-new solution for the recovery of acidic media.

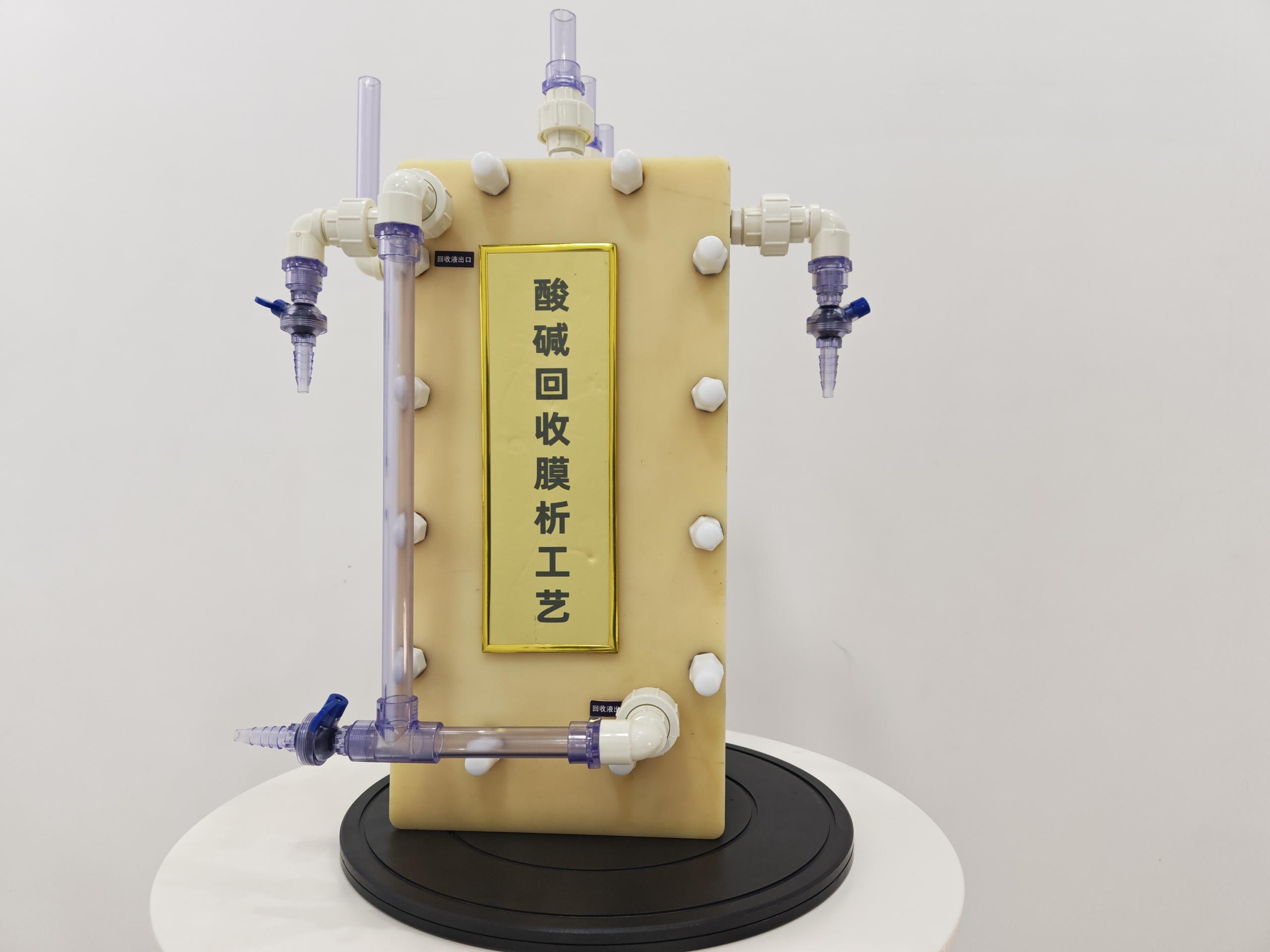

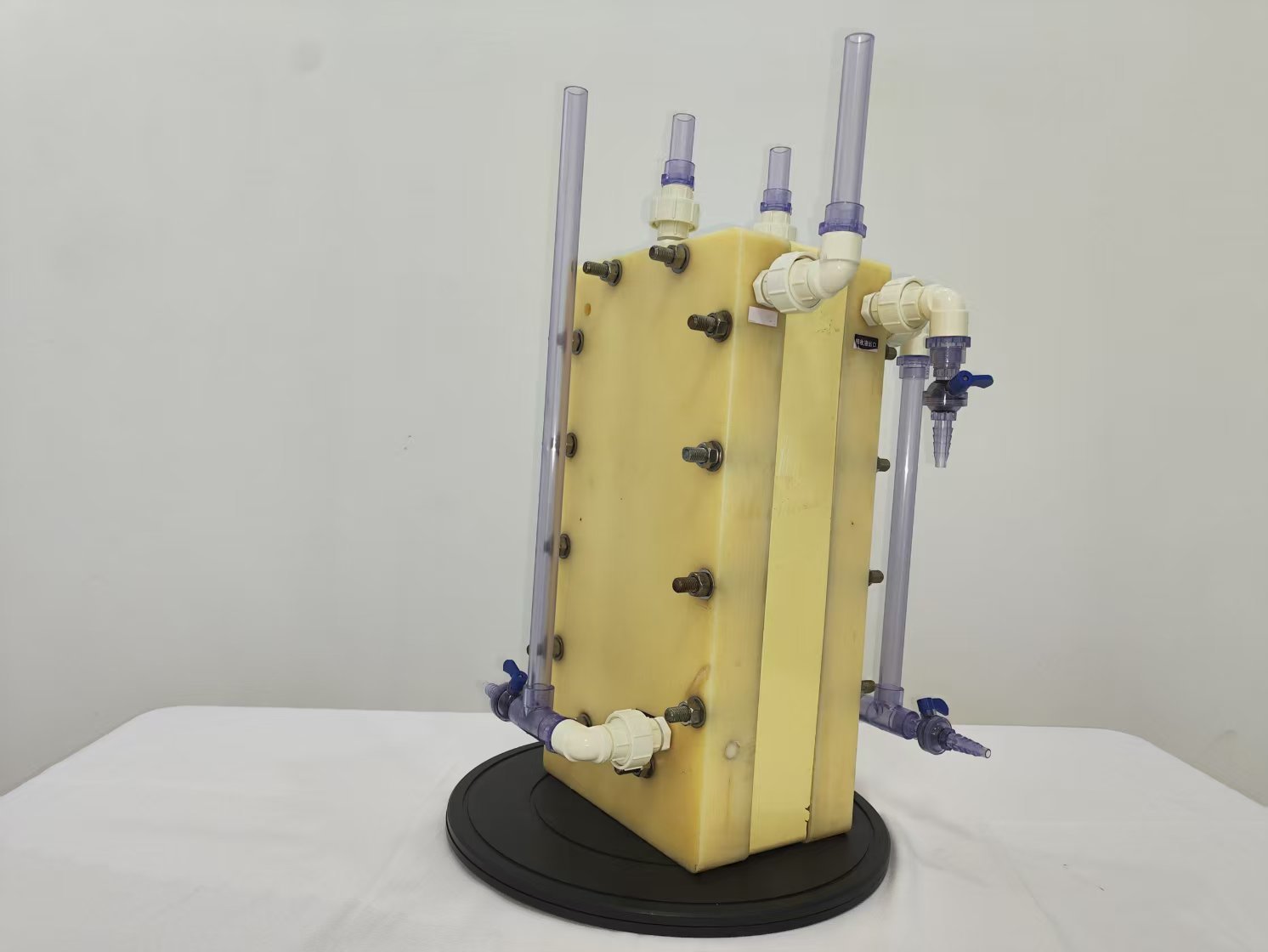

I. Technical Core: Precise separation driven by Concentration Difference

Membrane chromatography achieves molecular-level separation relying on concentration gradients. The core device consists of an ion-exchange membrane, a feed chamber and a recovery chamber. Take the recovery of phosphoric acid by anion exchange membranes as an example: The positively charged anion membrane allows phosphate ions to pass through while intercepting positively charged metal ions. Under the effect of concentration difference, phosphate ions in the feed chamber migrate towards the recovery chamber, while hydroxide ions in the recovery chamber diffuse in the reverse direction and combine with hydrogen ions in the feed chamber to form water. Eventually, high-purity phosphoric acid is obtained in the recovery chamber, and residual metal salt liquid is retained in the feed chamber. This process does not require an electric field or high temperature and high pressure, and has extremely low energy consumption. Data shows that its phosphoric acid recovery rate reaches 70% to 90%, the metal ion retention rate exceeds 90%, and the concentration of the recovered acid can reach over 80% of the original solution, which can be directly reused in the leaching process, significantly reducing the cost of new acid.

Ii. Significant Advantages: Dual benefits of greenness and economy

Efficient recycling of resources

Rare earth/metallurgical leachate contains 5% to 15% free acid and a large number of metal ions. Traditional treatment methods result in a waste of resources. Membrane chromatography can recover over 80% of free acid, which can be reused after simple treatment. For instance, in the rare earth leaching solution, over 85% of phosphoric acid can be recovered while over 90% of rare earth ions are retained, achieving a "acid-metal" dual cycle.

Low-carbon and environmentally friendly features

Compared with evaporation concentration or chemical precipitation methods, membrane chromatography does not require high temperatures or chemical agents, reducing energy consumption by more than 60%, and does not produce salt-containing wastewater or hazardous waste sludge, thus reducing pollution from the source. Treating one ton of rare earth leaching waste liquid can reduce approximately 0.3 tons of CO₂ emissions, which is in line with the "dual carbon" goals.

Flexibly adapt to scenarios

Membrane chromatography has a strong tolerance to fluctuations in the composition of the leachate and can handle single acid or mixed acid systems (such as phosphoric acid/oxalic acid mixed acid). By adjusting the membrane type (anion membrane/cation membrane) and operating parameters (flow rate, temperature), the separation efficiency can be optimized. Even under alkaline conditions, the cation membrane can be used to recover caustic soda, thus expanding into the field of soda ash production.

Iii. Existing Challenges and Optimization Paths

Membrane fouling and lifespan issues

Suspended solids, organic matter and other substances in the leachate are prone to clogging the membrane pores. When the solid mass fraction of the waste liquid exceeds 1-2 μg/g, the risk of pollution increases sharply. This problem can be alleviated by developing anti-pollution membrane materials (such as surface-modified membranes), adding pretreatment units (such as ultrafiltration), and adopting pulse flow or backwashing technologies.

The balance between efficiency and energy consumption

Due to the limitations of the solute diffusion coefficient and concentration difference, the traditional membrane chromatography treatment cycle is relatively long. In the future, efficiency can be enhanced while maintaining low energy consumption by developing highly selective membranes (such as gradient pore membranes), optimizing flow channel designs (such as helical winding components), or coupling with technologies like electrodialysis.

Integration and intelligent upgrade

At present, most membrane analysis systems are single modules and need to develop towards full-process integration: build a complete process of "pretreatment - membrane analysis - post-treatment" to enhance the recovery rate of resources. Introduce an intelligent monitoring system to regulate parameters such as concentration difference and flow rate in real time. Develop modular devices to lower the application threshold for small and medium-sized enterprises.

Iv. Future Prospects

From technological breakthroughs to industrial upgrading, with the tightening of global resource recycling policies and the improvement of environmental protection standards, the application potential of membrane analysis technology is huge. It is expected that by 2030, the global market size of rare earth/metallurgical waste liquid treatment will exceed 12 billion US dollars, and the proportion of membrane analysis is expected to exceed 30%. Technically, new materials such as amphoteric ion-exchange membranes and photocatalytic self-cleaning membranes will expand their application boundaries.

In terms of industry, by collaborating with fields such as hydrometallurgy and electrochemical deposition, cross-industry solutions can be formed. For instance, the combination of membrane dialysis and bipolar membrane electrodialysis can achieve the full-chain resource utilization of "acid recovery - metal purification - alkali regeneration", promoting the industry to move towards zero emissions.

Membrane chromatography technology, with its low energy consumption, high selectivity and environmental friendliness, precisely meets the green transformation demands of the rare earth/metallurgical industry. With the deep integration of membrane materials and process engineering, they will upgrade towards integration and intelligence, providing strong support for global resource recycling and sustainable development.

Related Products

Practical application of nitrogen and fluorine removal technology for flue Gas Washing Wastewater in the Thermal Power, heating and coal-fired Boiler industries

2025-08-15

Membrane separation: Green and efficient acid recovery for rare earth metallurgical leachate

2025-08-13

Electrodialysis experimental machine: Technical Practice of Concentrating and purifying Waste acid

2025-08-11

Electrodialysis: The "Resource Revolution" for Chemical/Pharmaceutical Wastewater, the Breakthrough from pollution Control to Recycling

2025-08-06

Huanke Environmental Protection Technology

HOTLINE:

Address:Optoelectronic Industry Accelerator in Weifang Hi-Tech Zone, Shandong Province, China

Contact:Zhang Gong

WhatsApp:+8619953608211

Email:eco.eqpt@gmail.com

Consult

TikTok

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd