16

2025

-

07

Ultrafiltration + homogeneous membrane electrodialysis: an efficient synergistic solution for water reuse in coal chemical industry

Author:

In the coal chemical industry, the characteristics of high water consumption and pollution make water reuse a key link in practicing green development, and the combination process of “ultrafiltration + homogeneous membrane electrodialysis” has become the preferred solution in this field due to its high efficiency and synergy.

As a pre-treatment link, ultrafiltration, relying on ultrafiltration membrane with a pore size of only 0.01-0.1 micron, can accurately retain suspended solids, colloids, microorganisms and macromolecules in the coal chemical wastewater, with a removal rate of more than 95%. After treatment, the turbidity of the effluent is reduced to below 0.1NTU, and the SDI (pollution index) is ≤3, which can effectively avoid the blockage of the subsequent membrane module due to the deposition of impurities and lay a foundation for the stable operation of the homogeneous membrane electrodialysis system.

Homogeneous membrane electrodialysis as the core depth treatment process, through the alternating arrangement of homogeneous anion and cation exchange membrane, driven by electric field to realize ion directional migration. The sodium ion, chloride ion and other salts in the wastewater are efficiently removed in the fresh water chamber, and the desalination rate can reach more than 90%; at the same time, the concentrated water chamber is enriched with high-concentration salts, and the industrial salt can be recovered through evaporation and crystallization to realize the recycling of resources. The process does not need to add chemicals, the whole operation at room temperature, energy consumption is only 1/3 of the traditional evaporation method, and the homogeneous membrane has the characteristics of pollution-resistant, long service life, significantly reducing the operation and maintenance costs.

After the application of this process in a coal chemical project, the water reuse rate has increased from 50% to more than 85%, with an annual water saving of more than 2 million tons; the effluent water quality meets the reuse standards for circulating cooling make-up water, process water, etc., with a COD ≤ 50mg/L and a total hardness of ≤ 100mg/L; the purity of the recovered industrial salt reaches 98%, and the annual economic benefit is more than 3 million yuan.

“Ultrafiltration + homogeneous membrane electrodialysis” process through the efficient synergy of pretreatment and deep treatment, not only solves the problem of complex composition of coal chemical wastewater, treatment difficulty, but also realizes the double recovery of water resources and salt resources, for the industry to save water, reduce emissions, reduce costs and increase efficiency to provide a reliable path of technology to help the coal chemical industry to the low-carbon recycling mode of transformation. It helps the coal chemical industry to transform into a low-carbon recycling mode.

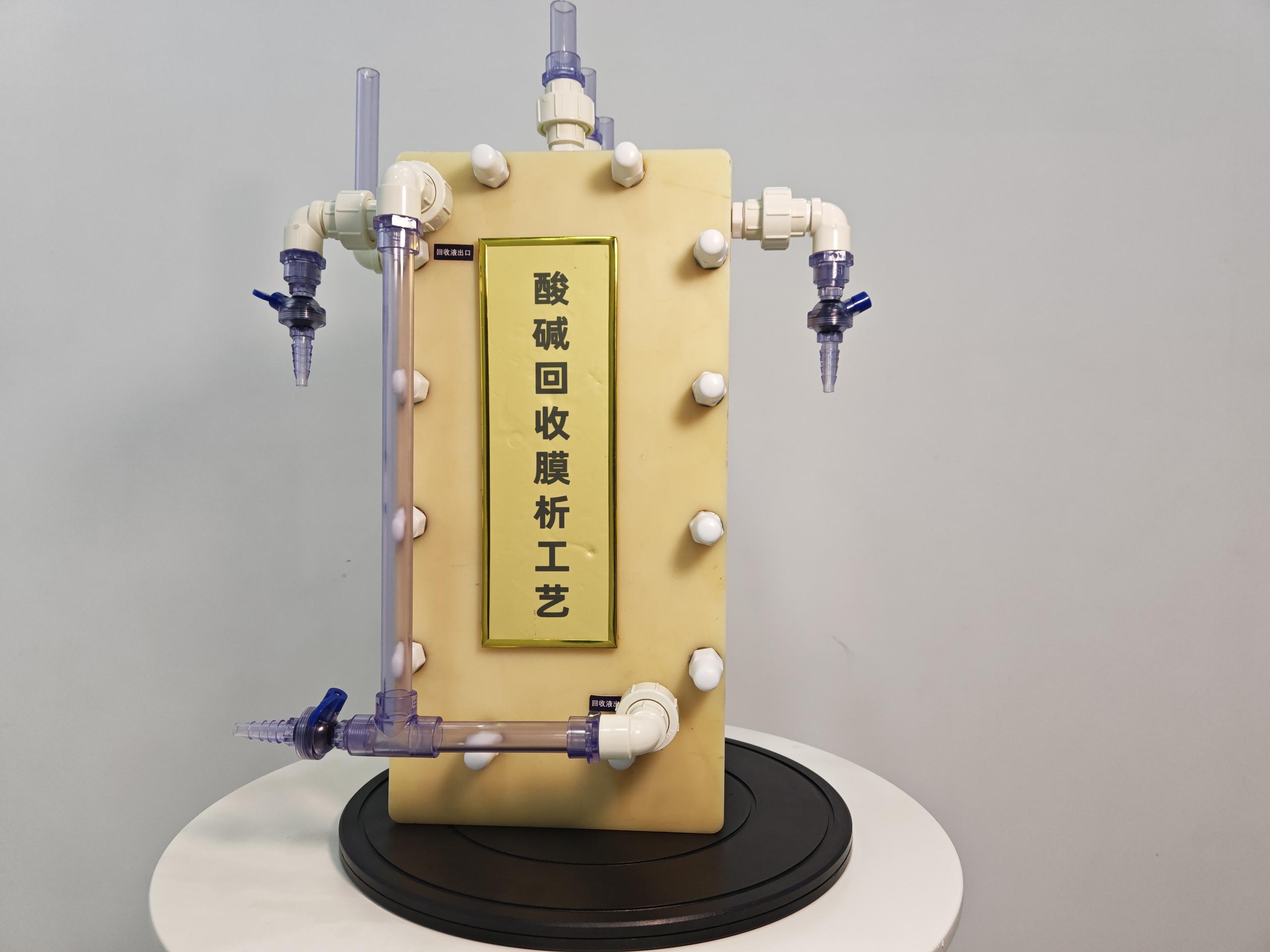

Related Products

Ultrafiltration + homogeneous membrane electrodialysis: an efficient synergistic solution for water reuse in coal chemical industry

2025-07-16

Homogeneous membrane electrodialysis: cracking the problem of zero discharge of high salt wastewater in zirconia industry

2025-07-14

Membrane analysis technology empowers titanium dioxide industry: waste sulfuric acid recovery realizes resource recycling

2025-07-10

Application of Membrane Dialysis in Waste Acid Recovery of Iron and Steel Industry

2025-07-07

Huanke Environmental Protection Technology

HOTLINE:

Address:Optoelectronic Industry Accelerator in Weifang Hi-Tech Zone, Shandong Province, China

Contact:Zhang Gong

WhatsApp:+8619953608211

Email:eco.eqpt@gmail.com

Consult

TikTok

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd