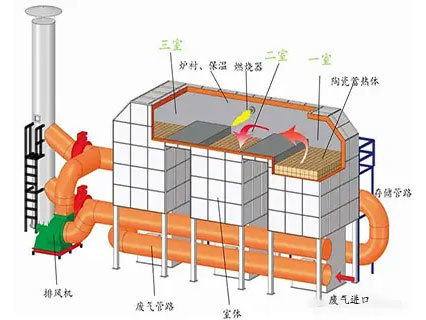

RTO (regenerative thermal oxidation technology)

RTO是指蓄热式热氧化技术,其原理是把有机废气加热到760摄氏度以上,使VOCs氧化分解成二氧化碳和水。氧化产生的高温气体流经特制的陶瓷蓄热体,使陶瓷体升温而蓄热,此“蓄热”用于预热后续进入的有机废气,从而节省废气升温的燃料消耗。陶瓷蓄热体分成两个及以上的区或室,每个蓄热室依次经历蓄热-放热-清扫等程序,周而复始,连续工作。蓄热室“放热”后立即引入部分已处理合格的洁净排气对蓄热室进行清扫(以保证VOCs去除率在95%以上),“清扫”完成后才能进入蓄热程序。

Keywords:

Tel:

HOTLINE:400-678-1829

ZHANG GONG:+86-18865361829

Detail

Detail

(1) Process Introduction

RTO refers to regenerative thermal oxidation technology, which heats organic waste gas above 760 degrees Celsius to oxidize and decompose VOCs into carbon dioxide and water. The high-temperature gas generated by oxidation flows through a specially designed ceramic heat storage body, causing the ceramic body to heat up and store heat. This "heat storage" is used to preheat the subsequent organic waste gas, thereby saving fuel consumption for exhaust gas heating. The ceramic heat storage body is divided into two or more zones or chambers, and each chamber undergoes the procedures of heat storage, heat release, and cleaning in sequence, repeating the cycle and working continuously. After the heat storage chamber releases heat, a portion of the treated and qualified clean exhaust gas is immediately introduced to clean the chamber (to ensure a VOCs removal rate of over 95%). Only after the "cleaning" is completed can the heat storage program be entered. Widely used domestically and internationally for the treatment of oven exhaust gas in painting processes, as well as for similar exhaust gas treatment in chemical and electronic industries. Applicable waste gas: medium to low concentration 100-3500mg/m3, with a decomposition efficiency of 95%~99%.

|

|

(2) Technological advantages

① Almost all waste gases containing organic compounds can be treated;

② The elasticity of handling organic waste gas flow is high (20-120% of nominal flow);

③ Can adapt to changes and fluctuations in the composition and concentration of VOC in organic waste gas;

④ Not sensitive to small amounts of dust and solid particles carried in the exhaust gas;

⑤ High thermal efficiency (>95%) among all thermal combustion purification methods;

⑥ Under appropriate exhaust gas concentration conditions, self heating operation can be achieved without the need to add auxiliary fuel;

⑦ Low maintenance workload, safe and reliable operation;

⑧ Organic sediment can be periodically removed, and the heat storage body can be replaced;

⑨ The pressure loss of the entire device is small and the service life is long.

|

|

ONLINE MESSAGE

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible

Related Products

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd