Biological deodorization filter

Biological deodorization filter technology is a biological deodorization technology that lies between biological washing method and biological filtration method. The drip filtration tower in the biological deodorization filter technology has both liquid phase regeneration and exhaust gas absorption functions.

Keywords:

Tel:

HOTLINE:400-678-1829

ZHANG GONG:+86-18865361829

Detail

Detail

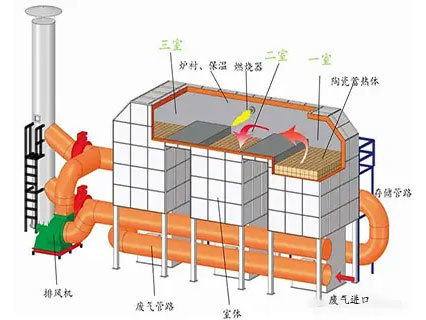

(1) Process Introduction

Biological deodorization filter technology is a biological deodorization technology that lies between biological washing method and biological filtration method. The drip filtration tower in the biological deodorization filter technology has both liquid phase regeneration and exhaust gas absorption functions. The tower is equipped with many fillers that can provide good growth and reproduction conditions for special microorganisms, creating a good environment for the degradation and absorption of odor. When the biological deodorization filter begins to operate, gas will flow into it from the bottom of the tower. During the flow process, the inoculated biofilm biofilter material present in the tower will continuously purify the gas flowing through it until the airflow is completely purified and discharged from the top of the tower. Compared to other biofiltration methods, the reaction conditions such as humidity and pH value of biofilter technology are easier to control. At the same time, compared to general biofiltration methods, the unique biofilter tower of biofilter technology can filter out acidic metabolic pollutants formed by microorganisms such as nitrogen and sulfur during the degradation process.

(2) Structural characteristics

① The deodorization device is composed of equipment shell, biological filler, spray (or pre treatment humidification) system, gas distribution system, etc;

② The biological deodorization filter should adopt a horizontal structure and a closed type according to the on-site conditions. The shell is achieved with sufficient stiffness and strength through a steel structure skeleton, and the inner shell is applied to avoid corrosion;

③ In addition to the intake and exhaust ports, the shell of the biological deodorization filter should also be equipped with relevant observation windows, steel structure ladders, maintenance platforms and inspection ports, and filler discharge ports;

④ Due to the uneven flow of odor inside the device, the treatment effect is reduced. So design corresponding diversion devices, such as gas distribution pipelines or channels, to solve the problem of uneven gas distribution and prevent short flow and channel flow;

⑤ The deodorization biological filter should be equipped with an insulation layer, and the outer shell should be made of stainless steel material above 304, with a thickness of 0.3mm;

⑥ The glass fiber reinforced plastic inner shell equipment of the deodorizing biological filter is composed of an inner lining anti-corrosion layer, a structural layer, and an outer surface layer from the inside out. The thickness of the inner layer of fiberglass steel plate is 6mm+carbon steel skeleton (the carbon steel skeleton in contact with the exhaust gas inside the box is made of fiberglass anti-corrosion, three layers of epoxy resin+two layers of 0.2mm fiber cloth)+SS304 shell (0.3mm);

⑦ The filler support layer inside the deodorizing biological filter is made of fiberglass grating plate (FRP plate, thickness ≥ 38mm), and the filler support layer should ensure sufficient stiffness, strength, and corrosion resistance. The strength of the supporting layer and support should not only consider the weight of the filler, but also factors such as the growth of biofilm and water holding capacity of the filler.

ONLINE MESSAGE

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible

Related Products

Huanke Environmental Protection Technology

HOTLINE:

Address:Gongye 1st Street, Weicheng District, Weifang City, Shandong Province China

Contact:Zhang Gong

Phone:+86-18865361829

Email:sdhuanke@163.com

Consult

Copyright © 2023 Shandong Huanke Environmental Protection Technology Co., Ltd